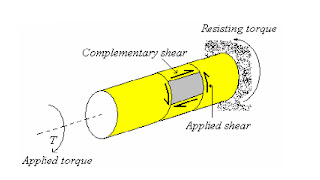

When a uniform circular shaft is subjected to a torque it can be shown that every section

of the shaft is subjected to a state of pure shear.

Assumptions

1. The material is homogeneous, i.e. of uniform elastic properties throughout.

2. The material is elastic, following Hook's law with shear stress proportional to

shear strain.

3. The stress does not exceed the elastic limit of proportionality.

4. Circular sections remain circular.

5. Cross sections remain plane.

6. Cross sections rotate as if rigid.

Angle of Twist (θ)

After applying the torque point A moves to point B and made an angleθ .

Modulus of Rigidity (G)

It is a measure of how much deformation the material would undergo subjected to a

Stresses

Composite Shafts

• Series Connection

When two similar or dissimilar shafts of the same or of different materials are connected

together to form one composite shaft, the driving torque being applied at one end and the

resisting torque at the other, the shafts are said to be connected in series.

Consider each component shaft separately, applying the torsion theory to each in turn.

The composite shaft will therefore be as weak as its weakest component.

Parallel Connection

If the driving torque is applied at the junction of the two shafts connected together and

the resisting torque at the other ends of the two shafts, then the shafts are said to be

connected in parallel.

The torque applied in this case is divided between the two shafts but the angle of twist is

the same for each shaft.

Power Transmitted by Shafts

If a shaft carries a torque T N.m and rotates at w rad/s it will do work at the rate:

P = Tw watts